Precise Electronics in Semi-Cap Equipment

Rapid Prototyping for Semiconductor Equipment Providers

Meeting Global Demand

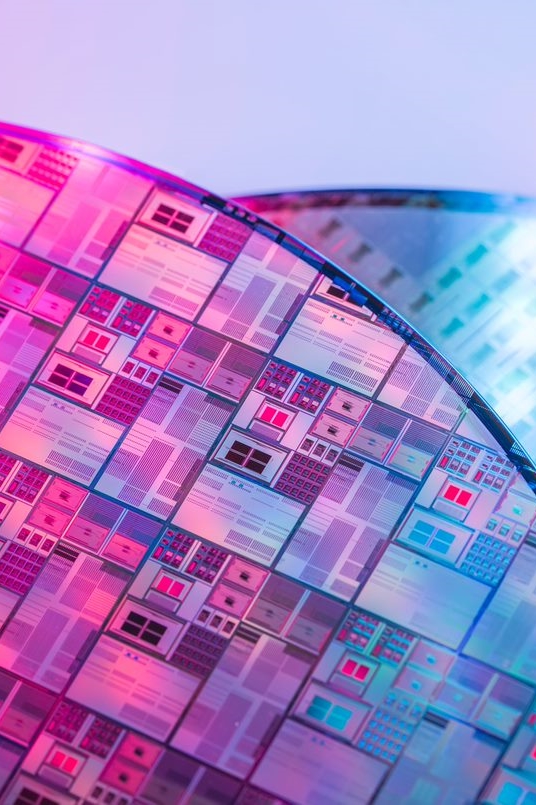

Recent years have posed stifling challenges to the semiconductor market that have led to worldwide shortages of integrated circuits (ICs) and memory devices. The combination of surging demand for consumer and automotive products and fully-utilized fabrication capacities has led to scarcity and increased prices in semiconductor devices.

The engine that drives the supply of new manufacturing facilities is revving up to deliver ample new devices to satisfy demand across all markets. Naprotek's agile electronics manufacturing capabilities are poised to aid leading manufacturers in expanding their capital equipment production to meet this global demand.

Meeting Global Demand

Recent years have posed stifling challenges to the semiconductor market that have led to worldwide shortages of integrated circuits (ICs) and memory devices. The combination of surging demand for consumer and automotive products and fully-utilized fabrication capacities has led to scarcity and increased prices in semiconductor devices.

The engine that drives the supply of new manufacturing facilities is revving up to deliver ample new devices to satisfy demand across all markets. Naprotek's agile electronics manufacturing capabilities are poised to aid leading manufacturers in expanding their capital equipment production to meet this global demand.

Driving Growth in Semi-Cap Equipment

Semi-Cap Equipment providers develop silicon transformation technologies including Atomic, Chemical Vapor, and Electrochemical Deposition (ALD, CVD ECD), Atomic Layer, Ion and Chemical Etch, Mass Metrology, and advanced lithography platforms including Extreme Ultraviolet (EUV) and Deep Ultraviolet (DUV) systems. While each of these fabrication processes poses its own distinct manufacturing requirements, Semi-Cap Equipment providers often rely on agile and rapid manufacturing approaches to manage waxing and waning production demand.

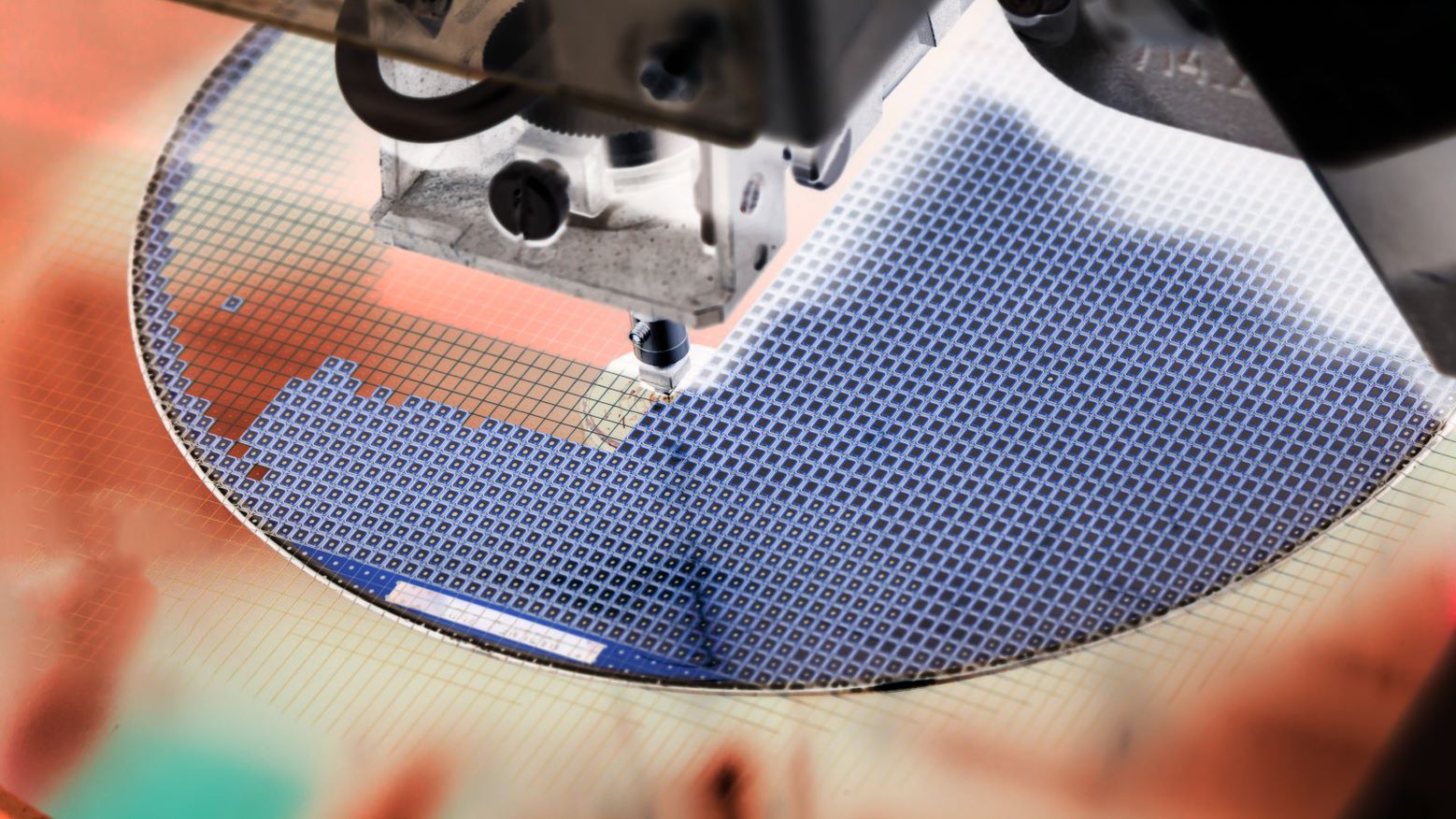

Naprotek has a dedicated rapid manufacturing facility specializing in the immediate turnaround of prototypes and batch production programs. For the Semi-Cap Equipment market in particular, we can deliver quotes in less than one day and provide a daily delivery schedule of PCBA’s to meet demand.

We Produce Assemblies for Every Point in the Silicon Ecosystem

Front-End Process Equipment

Surface Preparation

Chemical Vapor Deposition (CVD)

Chemical Mechanical Planarization (CMP)

Back-End Process Equipment

Wafer Inspection & Metrology

Wafer Dicing

Encapsulation

Automated Test Equipment

Wafer Probe

IC Chip Handler

Load Board

Multi-site

Rapid and Reliable Response Time

Naprotek's commitment to quality and reliability extends to meet the unique requirements of our semiconductor customers. Our teams and processes operate adeptly to deliver immediate quotes, high velocity prototyping, and unparalleled quick turn service.

Our customers deliver solutions to build the next-generation of semiconductor technologies used throughout the complete silicon ecosystem. Naprotek supports manufacturers delivering solutions for:

- Automated Test Equipment

- Inspection Equipment

- Metrology

- Microelectronics

- Semiconductor Packaging

- Thin Film Processing

- Wafer Fabrication

- Wafer Processing